What Is the Best Way to Insulate a Basement

Published on December 26, 2025 | By Attic Pro Care, Inc

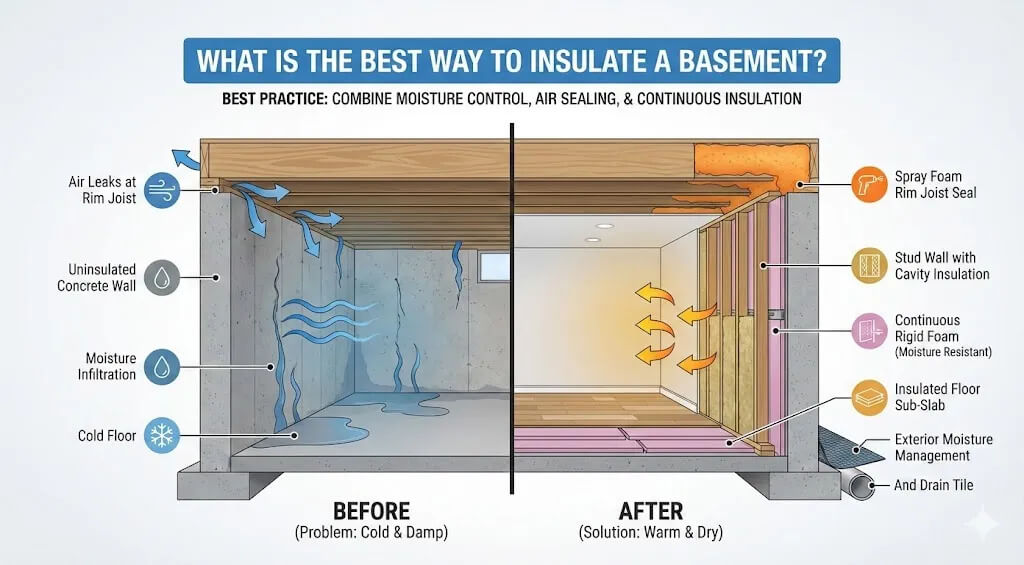

For builders and installers, basement insulation is not a cosmetic upgrade. It is a structural performance choice that shapes heating loads, humidity behavior, and play a crucial role in making the interior environment comfortable. Get it right and the building tightens. Get it wrong and problems migrate upward. Mold grows and complaints follow faster.

Underground environments behave differently. Walls are colder. Vapor moves inward. And heat escapes sideways instead of rising. Traditional building insulation logic fails here. For a successful insulation basement insulation must work with physics, not against it.

It’s not as simple as stuffing material into cavities. It is about selecting strategies that manage heat flow, air movement, and moisture pressure as a system.

Understand Basement Conditions Before Choosing an Insulation Strategy

A basement wall does not see the same world as a regular exterior wall. Soil buffers temperature but holds moisture. In winter, the wall sucks heat out of the underground structure. In summer, the reverse occurs and humidity is absorbed inward.

Available Forms

Fiberglass is available in pre-cut batts that match the standard wall stud spacing, rolls that are continuously installed, and loose fill that is blown into the attic or walls. The most significant type of new construction is the batts. Loose-fill suits are retrofit installations and are used at irregular locations.

Vapor drive matters here. Concrete is porous. Masonry breathes the surrounding moisture. Insulation if applied on the wrong side of the wall can trap moisture against cold surfaces leading to excessive condensation. The condensation builds up quietly and gradually.

Climate dictates risk. Cold climates demand higher R-values and tighter vapor control. Mixed climates complicate decisions with seasonal reversals. Warm climates shift the problem from heat loss to humidity management. But the basement is still located below the ground and is exposed to soil moisture

Before insulation is applied an array of factors need to be considered. Insulation installation depends heavily on external variables connected with the location. There is no one standard method for installation of installation. Builders will need to consider wall condition. Drainage quality. Water table behavior. Use of the space. Storage, mechanicals, living area, or future conversion. Each factor narrows the range of smart options.

Interior Basement Wall Insulation Strategies

Interior insulation is the most common approach. It avoids excavation. It controls cost. It fits retrofit work. But it carries risk if executed without restraint.

Rigid Foam Board Insulation

Rigid foam boards impose order on basement walls. They separate conditioned space from cold concrete. They resist moisture and perform reliably.

XPS, EPS, and polyisocyanurate each bring trade-offs. XPS delivers stable R-value and strong moisture resistance but raises environmental concerns. EPS offers breathability and lower cost with thicker assemblies. Polyiso performs well above grade but loses effectiveness in cold below-grade conditions.

Installation should be done precisely. Boards must be continuous. The seams should be sealed well and all gaps eliminated. Adhesion or mechanical fastening must fit uneven masonry surfaces. Any air gap behind the foam becomes a condensation pocket.

When installed directly against the foundation, rigid foam reduces thermal bridging and keeps interior framing warm. That warmth matters. Warm framing resists mold. Warm surfaces also resist condensation. Rigid foam is not a forgiving material and not easy to work with. But it delivers reliable results. Builders who value control often land here.

Spray Foam Insulation: Open-Cell vs Closed-Cell

Spray foam does seals completely. It fills and dominates assemblies.

Closed-cell spray foam delivers high R-value per inch. It performs the dual roles of being an air barrier and vapor retarder. It sticks solidly to concrete and masonry and tolerates irregular surfaces without complaint. It costs more, but it performs with authority.

Open-cell foam expands generously and seals air leaks but allows vapor movement. In basements, that permeability can be a liability unless paired with careful moisture management elsewhere. Open-cell foam belongs in controlled environments, not against chronically damp foundation walls.

Spray foam excels at complexity. Rim transitions. And Uneven substrates. It eliminates guesswork, but it demands skilled installers. Thickness control matters during application. Coverage consistency matters. Poor application undermines its promise quickly.

Use spray foam when air leakage is the primary enemy and budget allows decisive action.

Mineral Wool Insulation

Mineral wool insulation is another option. This material does not fear moisture. Moreover, it is flame-resistant. It absorbs sound. But it does not stop air on its own.

Used in basement walls, mineral wool requires an accompanying air and vapor control layer. Typically rigid foam or a membrane against the foundation, with mineral wool placed inboard within framing.

Its rigidity allows tight friction fits. Its permeability allows drying potential. Its fire resistance satisfies code pressures in mechanical-heavy basements.

Mineral wool is a systems player. Alone, it is incomplete. Integrated properly, it becomes resilient.

Exterior Basement Wall Insulation Strategies

Exterior insulation solves problems before they enter the building. It is elegant. It is effective. It is often impractical in retrofit scenarios.

Continuous Exterior Rigid Insulation

Exterior rigid insulation keeps foundation walls warm year-round. Condensation risk drops dramatically. Thermal mass works for the building, not against it.

Installed during new construction, this approach integrates cleanly with waterproofing and drainage systems. Boards protect membranes. Soil pressure stabilizes assemblies. Thermal continuity improves.

Retrofit exterior insulation requires excavation. Cost escalates. Access complicates. But when foundations are already exposed for repairs, the opportunity should not be wasted.

Exterior insulation is preventive medicine. High upfront cost. Low long-term regret.

Insulated Concrete Form (ICF) Systems

ICFs combine structure and insulation into a single system. Continuous insulation. Minimal thermal bridging. The end result is strong walls with quiet interiors.

For basement construction, ICFs simplify sequencing and deliver predictable thermal performance. They also demand planning. Mechanical penetrations. Interior finishes. Attachment details must be considered early.

Cost premiums exist. They are offset by performance, speed, and reduced detailing complexity. ICFs favor builders who think holistically and execute consistently.

Basement Floor Insulation Approaches

Heat loss does not stop at walls. Floors transmit cold relentlessly. Especially slabs tied directly to soil.

Insulating Under Concrete Slabs

Under-slab insulation changes everything. Rigid foam beneath the slab reduces heat loss, stabilizes interior temperatures, and improves comfort dramatically.

Vapor barriers belong below insulation, not above. Capillary breaks matter. Edge insulation at slab perimeters prevents thermal bypass.

In cold climates, under-slab insulation is not optional. It is foundational. Skipping it saves little and costs forever.

Insulating Over Existing Basement Slabs

Retrofit scenarios complicate floor insulation. Headroom becomes currency. Raised floor systems introduce layers that must manage moisture carefully.

Rigid foam topped with subfloor panels can work, but drainage, vapor control, and ceiling height limits must be respected. This approach is surgical, not casual.

Floor insulation retrofits require restraint. Sometimes walls deliver better returns.

Rim Joist and Band Joist Insulation Strategies

Rim joists leak energy with enthusiasm. They sit at the junction of structure and exterior. They are often ignored. They punish that neglect.

Spray foam dominates here for a reason. It seals irregular framing and blocks air leakage. It also resists condensation on cold surfaces.

Rigid foam cut-and-cobble methods can work if executed precisely. Gaps must be sealed. Edges foamed. No tolerance for sloppiness.

Rim joists are small areas with outsized impact. Insulate them well and the basement calms down. Miss them and performance suffers everywhere.

Climate-Specific Basement Insulation Strategies

Climate dictates risk. Risk dictates strategy.

In cold climates, insulation must keep interior surfaces warm. Vapor control becomes critical. Interior insulation must prevent condensation on foundation walls. Higher R-values are not optional. They are defensive measures.

In mixed climates, assemblies must handle seasonal reversals. Drying potential matters. Overly aggressive vapor barriers can backfire. Balance becomes the goal.

In warm climates, humidity drives decisions. Insulation still matters, but moisture control takes priority. Materials must resist mold and allow drying without sacrificing thermal resistance.

Climate ignorance is expensive. Builders who respect regional behavior build assemblies that endure.

Cost, ROI, and Long-Term Performance Comparison

Basement insulation costs are front-loaded. Savings accrue slowly. But failures surface quickly.

Rigid foam offers strong ROI through durability and predictability. Spray foam commands higher upfront costs but delivers immediate air-sealing benefits. Exterior systems cost more but reduce risk dramatically.

Long-term performance favors systems that control moisture first, heat second. Energy savings are meaningless if assemblies rot.

Smart builders sell performance, not price. Clients forget costs. They remember comfort and problems.

Choosing the Right Basement Insulation Strategy

There is no single best system. There is only the best fit. Budget sets boundaries. Climate sets rules. Use case sets priorities. Wall condition sets limits. Professional assessment should be done correctly. Guesswork is not an option at all. Builders who slow down at this stage move faster later.

Conclusion

Basement insulation is not about warmth alone. It is about control. Control over heat. Over moisture. Over long-term liability. Builders and installers who treat basements as strategic zones outperform those who treat them as afterthoughts. The difference shows up in energy bills, indoor air quality, and structural longevity. Insulate basements with intent. Keep the laws of physics in mind and execute cleanly.